Ampli: Construction Sets for Paperfluidics and Diagnostics

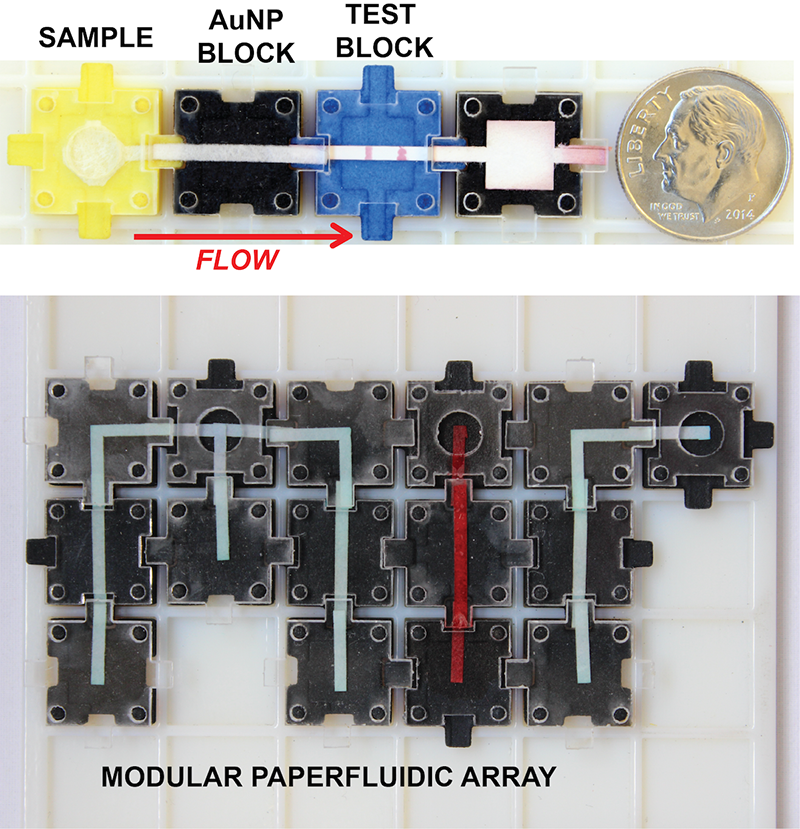

We developed Ampli diagnostic blocks after realizing that most paper diagnostics, while simple, were still subject to a lot of black box engineering. This renders the technology difficult to fabricate in low resource areas (where they stand to benefit the most). So we thought of the way electronics democratized fabrication by adopting breadboards where components enjoy hand placed modularity. No machining, special instruments or even hand dexterity is required to create a paperfluidic circuit. Biochemistry doesn’t have a breadboard, so we made one. Our goal was to create a plug and play set of blocks that could form, stop and modify reactions in real time. In glassware or microfluidics, this is almost impossible to do (the stopping and changing your mind part). Modular paper allows us to do that.

In our paper published in Advanced Healthcare Materials, we demonstrate our system with useful diagnostics for human health ranging from elemental glucose assays and infection diagnostics, to multiplexed peptide reporter cancer test and viral immunoassays. It was important to us that this worked with real reaction and not colored dyes because that can be a valley of death in the development of these systems.

While we are excited about lowering biofabrication barriers, we also discovered new forms of immunoassay enhancements not feasible in traditional systems, such as dynamically changing the direction of flow on paper, which leads to an substantially increased diagnostic signal. This will be particularly useful for “bloodless assays” for disease: saliva, sweat, water, or urine biomarkers where it’s easy to get a sample (no blood) but it’s the sample is very diluted. Some targets are HIV, cancer biomakers, and viruses like Zika where the levels of the disease are not high but still dangerous. Without external equipment, such as centrifuges, this is not possible with traditional paper diagnostic tests.

MEDIKit: DIY Technologies for Health

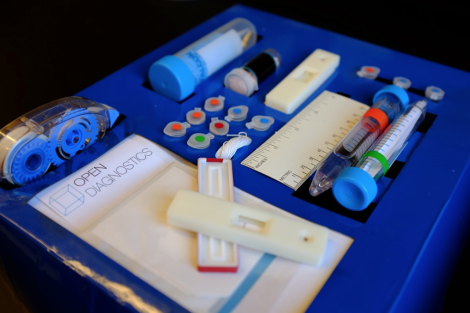

The core impact of this project stems from developing the design kits as a platform technology. Modular components allow medical professionals to design their own appropriate solutions that are more useful and sustainable to physicians and patients. Given the appropriate tools and the right context set by the course, MEDIKit users are empowered to innovate and address the unique challenges in their work environment.

The core impact of this project stems from developing the design kits as a platform technology. Modular components allow medical professionals to design their own appropriate solutions that are more useful and sustainable to physicians and patients. Given the appropriate tools and the right context set by the course, MEDIKit users are empowered to innovate and address the unique challenges in their work environment.

The MEDIKits span six areas of technology: drug delivery, diagnostics, microfluidics, prosthetics, vital signs and surgical devices. The kits contain a combination of medical device parts coded with a language of design, platform technologies that can be adapted, such as handheld microscopes, and materials to build and modify devices.

Our research into user-enabled medical prototyping continues at the lab. We are keenly interested in understanding the effects of shifting the power from the { expert + regulator } and sharing it with everyday { doctors + nurses + users } to make more transparent and accessible designs.

Open Access Diagnostics

Rapid diagnostic fabrication can be obscure in lab practice and may involve expensive biological assays and methods. We are create an open access distribution of our diagnostic devices so that anyone, anywhere in the world with access and the need for patient care can develop their own paper devices.